High-quality 317L Stainless Steel Coil

317L stainless steel coil, as a high-quality stainless steel material, has excellent corrosion resistance and mechanical properties, widely used in various fields.

Petroleum and chemical industries: 317L stainless steel coil is widely used in the manufacture of pipelines, storage tanks, reactors and other equipment because of its excellent corrosion resistance. It can resist the erosion of various chemical substances, ensure the long-term stable operation of the equipment, and improve production efficiency.

Food and beverage industry: The food and beverage industry places high demands on the safety and hygiene of materials. 317L stainless steel coil meets food safety standards, is non-toxic and tasteless, easy to clean and disinfect, so it is widely used in the manufacture of food processing equipment, catering utensils and packaging materials.

Medical device industry: The medical device industry has high requirements for the biocompatibility and corrosion resistance of materials. 317L stainless steel coil has good biocompatibility and corrosion resistance, which can meet the special needs of the medical device industry, such as manufacturing surgical instruments, implants, etc.

Construction industry: In the construction industry, 317L stainless steel coil is widely used in the manufacture of architectural decoration, railings, brackets and other fields because of its beautiful appearance and excellent corrosion resistance. It can improve the quality and life of the building and make the building lasting.

Automobile industry: In the automotive industry, 317L stainless steel coil is used to manufacture automotive parts, such as exhaust systems, car seats, etc. It can improve the corrosion resistance and mechanical properties of auto parts, improve the service life and safety of cars.

| Surface Finish | Definition | Application |

| 2B | Finished by heat treatment, picking, or equivalent cold rolling, followed by skin pass to obtain adequate luster surface. | With a bright and smooth surface, easy for further grinding to obtain a brighter surface, suitable for medical instruments, milk containers, tableware, and so on. |

| BA | Bright heat treatment after cold rolling. | Structural members .etc.kitchen utensils, cutlery, electric appliances, medical instruments, building decorations, etc. |

| NO.3/NO.4 | Polished with No.150-240 abrasives. | Milky food processing equipment, medical instruments, and building decorations. |

| HL | Finished by polishing with abrasives of suitable grain size to obtain continuous streaks. | Building decorations, such as elevators, escalators, doors, etc. |

| 6K/8K | A mirror-like reflective surface is obtained by polishing with successively finer abrasives and buffing extensively with all gridlines removed. | Building entrances, building column casting, elevator wall doors, counters, sculptures, etc. |

| Chemical composition and mechanical properties of stainless steel coils | |||||||||

| Grade | Chemical Composition (%) | Mechanieal Performece | |||||||

| C | Si | Mn | P | S | Ni | Cr | Mo | Hardness | |

| 201 | ≤0.15 | ≤1.00 | 5.5/7.5 | ≤0.060 | ≤0.030 | 3.5/5.5 | 16.0/18.0 | - | HB≤241,HRB≤100, HV≤240 |

| 304 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 8.0/11.0 | 18.00/20.00 | - | HB≤187,HRB≤90,HV≤200 |

| 316 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 10.00/14.00 | 16.0/18.0 | 2.00/3.00 | HB≤187, HRB≤90 HV≤200 |

| 316L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 10.00/14.00 | 16.0/18.0 | 2.00/3.00 | HB≤187, HRB≤90 HV≤200 |

| 410 | ≤0.15 | ≤1.00 | ≤1.25 | ≤0.060 | ≤0.030 | ≤0.060 | 11.5/13.5 | - | HB≤183, HRB≤88 HV≤200 |

| 430 | ≤0.12 | ≤1.00 | ≤1.25 | ≤0.040 | ≤0.03 | - | 16.00/18.00 | - | HB≤183, HRB≤88 HV≤200 |

| Stainless Steel Coil/Sheet/Plate Information | |||||||||||

| Technique | Surface Finish | Grade Series | Thickness(mm) | Width(mm) | Application | ||||||

| Main Dimension | |||||||||||

| 20-850 | 1000 | 1219 | 1240 | 1250 | 1500 | Petro-chemical industry, Tanks Construction material |

|||||

| Hot Rolled | No.1 / 2E | 201/202/ 304 |

2.2-12.0 | √ | √ | √ | √ | √ | |||

| Cold Rolled | 2B | 201/304 | 0.25-3.0 | √ | √ | √ | √ | √ | √ | ||

| 410S/430 | 0.25-2.0 | √ | √ | √ | √ | ||||||

| No.4 / Hairline Mirror / Linen SB |

201/304 | 0.22-3.0 | √ | √ | √ | √ | √ | ||||

| 410S/430 | 0.25-2.0 | √ | √ | √ | √ | √ | |||||

| BA | 201/304 | 0.2--1.8 | √ | √ | √ | √ | |||||

| 410S/430 | 0.25-2.0 | √ | √ | √ | √ | ||||||

| 2BA | √ | √ | √ | √ | |||||||

Stainless steel coil is widely used in construction, surgery, kitchen essentials, etc. 304 stainless steel is suitable for the construction of external banisters and handrails, and it has good processing performance and weldability. 316 stainless steel is suitable for kitchen essentials such as equipment, cutlery, and cookware, and it has good corrosion resistance and a wide range of shapes. 316L stainless steel is suitable for medical and surgical applications, which demand high levels of reliable performance.

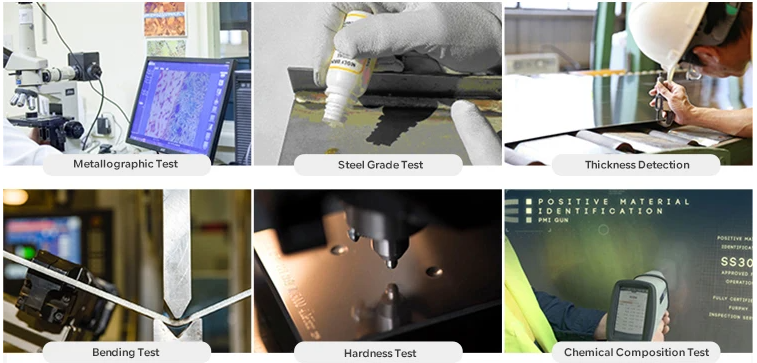

Regarding the quality control of Grand Metal, our products need to go through a series of strict quality control from production to delivery, including thickness testing, tensile testing, tensile testing, surface testing, color difference testing, packaging testing, etc. to ensure Our products are safely delivered to customers.

Export standard package,bundled or be required.

The inner size of container is below:

20ft GP: 5.8m(length) x 2.13m(width) x 2.18m(high)

40ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high)

40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high)

Delivery Details 7-15 dyas,or according to the order quantity or upon negotiation.