What is the grade of carbon steel sheet?

03-22-24

In the field of metal materials, carbon steel sheet is a widely used material with excellent mechanical properties and processing properties. The grade classification of carbon steel sheet mainly depends on its carbon content, sulfur content, phosphorus content and other alloying element content. Understanding these grade classifications helps us select the carbon steel sheet suitable for the specific application needs.

1) Carbon steel sheets are classified by carbon content

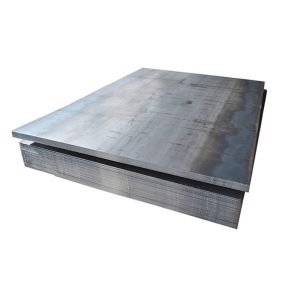

Carbon steel sheet is mainly composed of iron and carbon, of which the carbon content is usually between 0.03% and 2.0%. According to the different carbon content, carbon steel sheet can be divided into low carbon steel, medium carbon steel and high carbon steel. Low carbon steel, with a carbon content of less than 0.3%, has excellent weldability and plasticity, and is often used in the manufacture of pipes, containers, etc. The carbon content of medium carbon steel is between 0.3% and 0.6%, has good strength and wear resistance, and is often used in the manufacture of mechanical parts. High carbon steel carbon content of more than 0.6%, high hardness but poor toughness, often used in the manufacture of cutting tools, abrasives and so on.

2) Carbon steel sheets are classified according to their mechanical properties

In addition to classification based on carbon content, carbon steel sheets can also be classified according to their mechanical properties. For example, according to the tensile strength, yield strength, elongation and other indicators, carbon steel sheet can be divided into different grades. These grades are usually indicated on the product manual or material label so that users can choose according to their needs.

3) The grade of carbon steel sheet is selected according to the engineering requirements

In practical applications, the grade selection of carbon steel plates needs to be carried out according to specific engineering requirements. For example, for mechanical parts that need to withstand high loads and wear, it may be necessary to choose high-carbon steel or high-strength grade carbon steel sheets. For containers or pipes that require good plasticity and weldability, mild steel may be more suitable.

4) The grade of carbon steel sheet is also affected by other factors

The grade of carbon steel sheet will also be affected by factors such as its production process and heat treatment. Different production processes and heat treatment methods can change the organizational structure of carbon steel sheet, and then affect its mechanical properties and uses. Therefore, when selecting carbon steel sheet, in addition to considering its grade, it is also necessary to understand its production process and heat treatment method.

5) Sum up

In general, the grade classification of carbon steel plates is mainly divided according to the content of carbon, sulfur, phosphorus and other alloying elements. Understanding these grade classifications helps us to better select and apply carbon steel sheets. In practical applications, we need to choose the appropriate carbon steel sheet grade according to the specific use environment and requirements to ensure product quality and performance. At the same time, with the development of science and technology and the continuous emergence of new materials, the grade classification and application fields of carbon steel sheet will continue to expand and update. Therefore, we need to constantly learn and understand new materials and new technologies to adapt to the changing market demand and industrial development.