Corrosion-resistant Dx51d Color Coated PPGI Coil

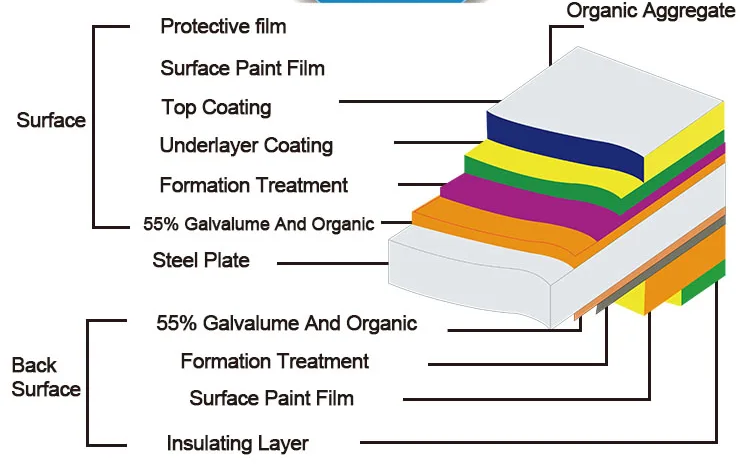

Dx51d color coated PPGI coil is made from high-quality steel that is coated with a layer of zinc for corrosion resistance. The zinc coating is then followed by a layer of paint, which not only enhances the aesthetic value of the material but also provides additional protection against rust and corrosion. The paint finish is available in a wide range of colors, allowing architects and designers to choose the perfect hue to complement their project's design aesthetic.

| Product Name | Pre-painted Galvanized Steel Coil |

| Thickness | 0.12~2.0 mm |

| Width | 600 mm~1250 mm |

| Coating | top coating 15+5um, back paint 7+3um, or customized |

| Coil Weight | 3-5mt |

| Colors | RAL Colors or as customer‘s requirements |

| Surface treatment | Top paint: FVDF, HDP, SMP, PE, PU Prime paint: polyurethane, epoxy, PE Back paint: epoxy, modified polyester |

| Standard | ASTM, JIS, EN |

| Certificate | ISO, CE |

| Payment terms | 30% T/T deposit in advance, 70% T/T balance within 5 days after B/L copy, 100% Irrevocable L/C at sight, 100% Irrevocable L/C after receive B/L 30-120 days |

| Delivery times | 8-15 days after the receipt of deposit |

| Package | tied up with steel strips and wrapped with water proof paper |

| Application | Widely used in roofing sheet, window-shades, car ceiling, the shell of the car, air conditioner, outer shell of water machine, steel structure etc |

Hot-dip galvanized color coated steel sheet(pre-painted galvanized steel sheet) The product obtained by coating an organic coating on a hot-dip galvanized steel sheet is a hot-dip galvanized color-coated plate. In addition to the protective effect of zinc, the hot-dip galvanized color-coated sheet also protects against rust and has a longer service life than hot-dip galvanized sheet;

Hot-dip aluminum-zinc color coated sheet(pre-painted gavanized steel sheet) Hot-dip aluminum-zinc steel sheets can also be used as color-coated substrates (55% AI-Zn and 5% AI-Zn);

Electroplated zinc color coated sheet

The electro-galvanized sheet is used as the substrate, and the product obtained by baking with the organic coating is an electro-galvanized color-coated plate. It has a beautiful appearance and excellent processing properties, and therefore can be mainly used for home appliances, audio, steel furniture, interior decoration, and the like.

Polyester (PE): Good adhesion, rich colors, wide range in formability and outdoor durability, medium chemical resistance, and low cost.

Silicon modified polyester(SMP): Good abrasion resistance and heat resistance, as well as good external durability and chalking resistance, gloss retention, general flexibility, and medium cost.

High Durability Polyester(HDP): Excellent color retention and anti-ultraviolet performance, excellent outdoor durability and

anti-pulverization, good paint film adhesion, rich color, excellent cost performance.

Polyvinylidene Fluoride(PVDF): Excellent color retention and UV resistance, excellent outdoor durability and chalking resistance, excellent solvent resistance, good moldability, stain resistance, limited color, and high cost.

Good durability and long life compared with galvanized steel.

Good heat resistance, less discoloration at high temperature than galvanized steel.

Good thermal reflectivity.

Processability and spraying performance similar to galvanized steel.

Good welding performance.

Good performance-price ratio, durable performance and extremely competitive price.